Building a sustainable future

Converting Natural Gas into Hydrogen and Net-Zero Infrastructure

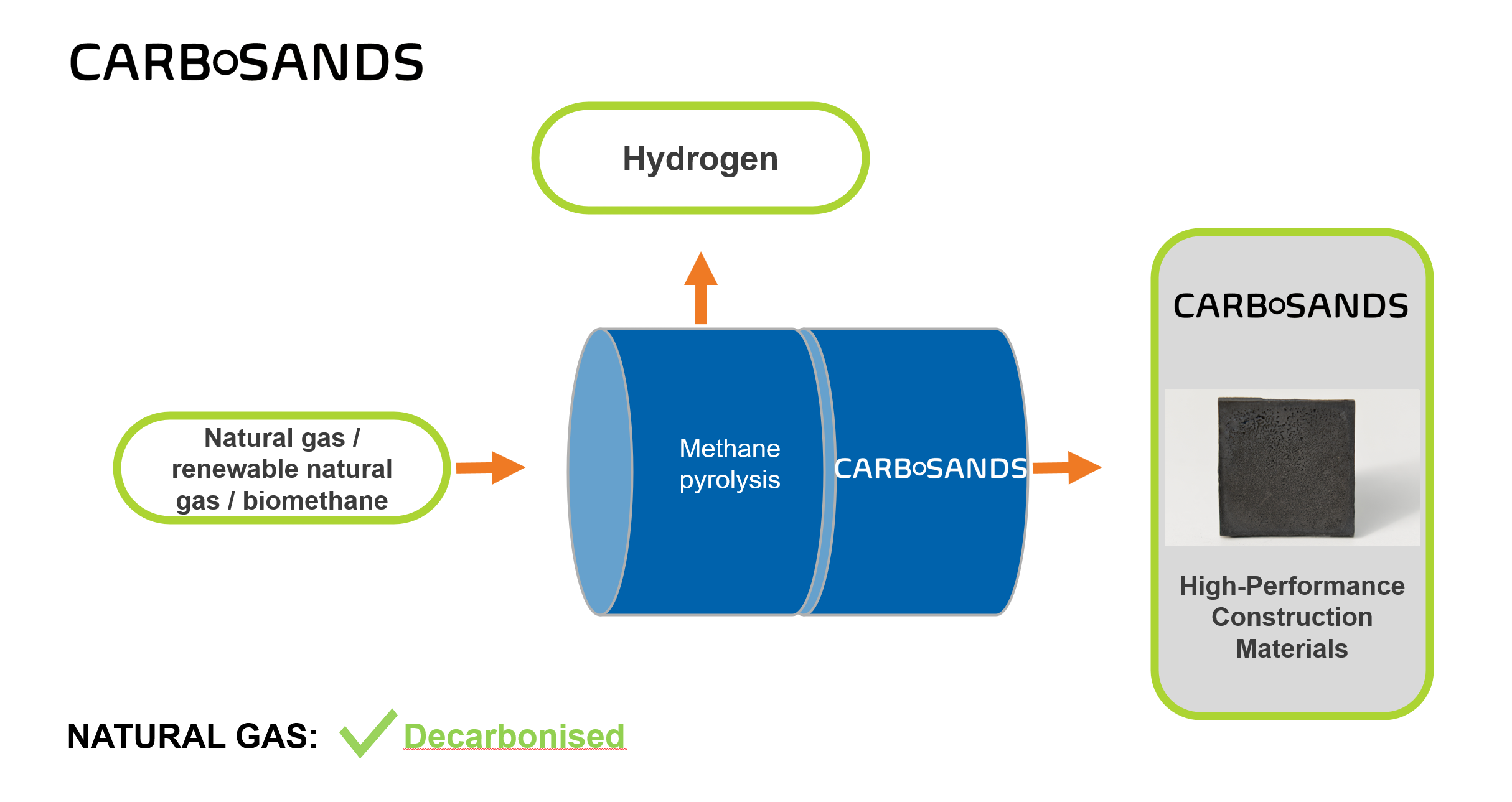

The industry is under increasing pressure to decarbonise while maintaining the value of existing assets. CARBOSANDS provides a transformative solution: converting natural gas and biomethane into clean hydrogen and performance materials, with no CO₂ emissions.

This is made possible through methane pyrolysis, which splits methane into hydrogen and solid carbon. While the pyrolysis step is well established, the true innovation lies in what happens next:

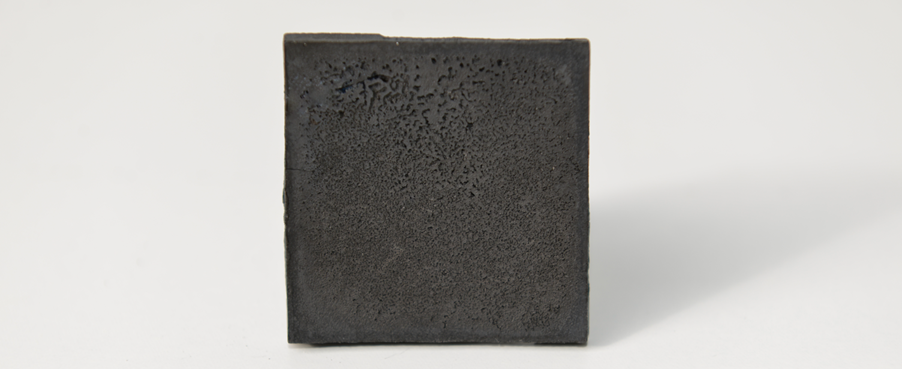

We have developed a combined system consisting of a specially designed moving or fluidised bed reactor and a proprietary, patented granulate manufacturing process that upgrades solid carbon into a high-performance material.

The resulting carbon granulate is specifically engineered for use in high-performance construction materials with both organic and inorganic binders. It can even replace construction sand in concrete — unlocking access to a gigaton-scale market. Unlike conventional fillers, it resists compressive, tensile, and shear forces. Its engineered sharp edge geometry and optimised particle size distribution make it ideal for demanding structural applications. In this form, the carbon is effectively immobilised — and can remain so indefinitely through continuous recycling.

CARBOSANDS enables:

1C + 4H — The Perfect Molecule

Unlocking the full potential of methane

Why burn methane / CH4 and waste its carbon as CO₂?

CARBOSANDS converts natural gas and biomethane into clean hydrogen and a functional building material — with zero emissions.

→ A dual-value innovation for a net-zero world.

The CARBOSANDS USP:

Two valuable products. Zero emissions.

The CARBOSANDS Business Case

We use methane pyrolysis to split methane without combustion:

-

Hydrogen → clean energy carrier

-

Solid carbon → raw material for mass applications in construction

Our patented process combines:

-

A specially designed moving/fluidised bed reactor

-

A unique granulate production system that shapes the carbon into

-

Angular particles with high mechanical resilience

-

Size distributions ideal for binder integration

-

CARBOSANDS enables the simultaneous production of two valuable products: clean hydrogen and a solid carbon material that can be used as a construction feedstock for both drywall and concrete. While hydrogen generates a very significant economic value as a clean energy carrier, the solid carbon product opens entirely new markets in the building materials sector. In addition to the value created from hydrogen sales, CARBOSANDS unlocks a significant market potential of its own, positioning it as a dual-output platform technology with a substantial climate and economic impact.

The result:

From carbon neutral to climate positive

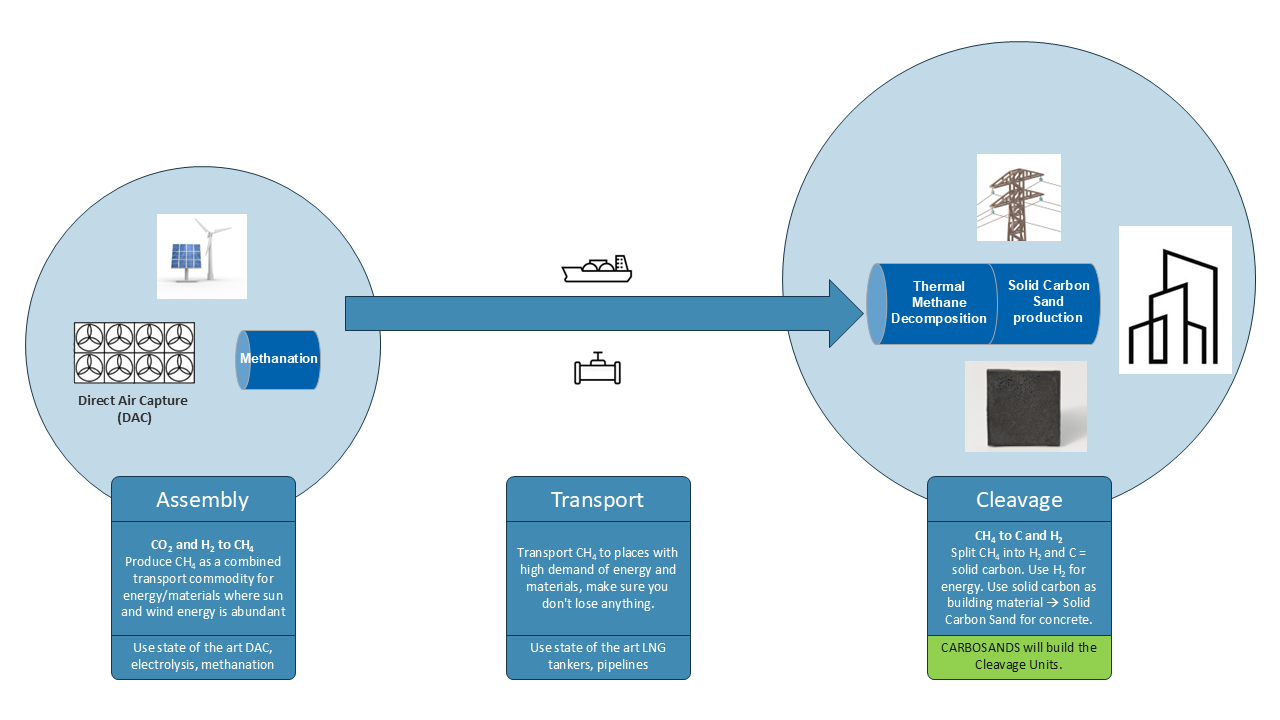

The highway from Direct Air Capture to Buildings

When sourced from biomethane/renewable natural gas, CARBOSANDS does more than avoid emissions — it enables the direct removal of atmospheric CO₂ through permanent carbon embedding in infrastructure. And the impact doesn’t end there:

Because CARBOSANDS granulate is designed for full recyclability within concrete and binder systems, the carbon remains permanently immobilized across life cycles. This turns construction materials into a scalable, decentralized carbon sink — with virtually infinite sequestration potential.

Each tonne of embedded solid carbon permanently sequesters approximately 2–3 tonnes of CO₂-equivalent. At a substitution level of 3 billion tonnes per year, this corresponds to a global sequestration potential of up to 9 billion tonnes of CO₂ annually. Coupled with low-emission hydrogen production via methane pyrolysis, CARBOSANDS offers an economically viable, industrially scalable pathway for CO₂ removal and the decarbonisation of construction—paving the way for truly net-zero infrastructure.

CARBOSANDS – Connecting the dots